How Earth Smart® Post-Consumer

PET is Unique

Since Post-Consumer PET flake requires extensive cleaning to remove impurities, many packaging companies can only utilize a small portion of Post-Consumer PET without compromising optics.

Our new state-of-the-art technology gives us the unique ability to produce up to 50% Post-Consumer PET with superior clarity. This is available for our entire line of PET products.

Post-Consumer PET can be utilized for D&W Fine Pack’s entire line of PET products.

View examples below, check out our PET catalog, or Contact Us today!

50% PCR Manufactured PET with superior clarity

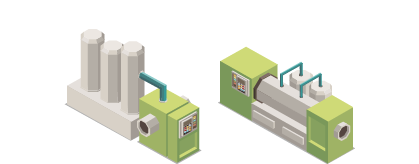

1: D&W’s sophisticated contaminant removal system allows a broader range of post consumer PET to be utilized as input into their manufacturing process.

2: With all contaminants removed during extrusion, the result is a PET sheet free from all impurities and ready for thermoforming.

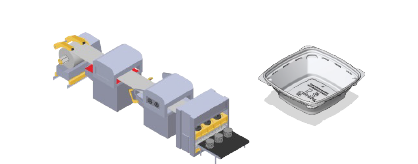

3: D&W’s final output is crystal clear PET packaging that can be made with 50% PCR without sacrificing optics.

Higher Quality - Greater Clarity - More Sustainable

D&W’s extrusion process utilizes a state-of-the-art extrusion system, allowing us to take non-FDA grade recycled PET and turn it into high quality FDA approved food packaging.

What does this mean for our customers?

- Premium Quality sheet with fewer imperfections than others in the market

- Clear PET packaging, with superior optics

- Higher Utilization of recycled PET that would have otherwise gone to the landfill

- Better security of supply vs. the competition since our extrusion system allows for a broader range of input materials

Full PET Product Offering

450 Unique SKUs which can be produced at 50% PCR.

2-Piece Bowls, Containers & Lids

Round, Rectangular, Square & Oblong

Standard & Tamper-evident Lids Available

180 Unique SKUs

Trays

Round, Rectangular & Square

Single & Multicompartment

80 Unique SKUs

Bakery Bases & Lids

Round & Rectangular Cake Bases & Lids

Pie Bases & Lids

50 Unique SKUs

Hinged Containers

Bakery, Produce & Multi-purpose

140 Unique SKUs

50% Post Consumer Crystal View® Bowls and Lid

Part Number | Description | Diameter | Height | Case Weight | Case Ct. | Cube | Ti x Hi |

|---|---|---|---|---|---|---|---|

CVB716-R5 | 16 oz. Crystal View Bowl | 6.78″ | 1.62″ | 10.89 | 300 | 3.00 | 5 x 5 |

CVB724-R5 | 24 oz. Crystal View Bowl | 6.78″ | 2.80″ | 13.11 | 300 | 3.20 | 5 x 5 |

CVB732-R5 | 32 oz. Crystal View Bowl | 6.78″ | 3.26″ | 15.29 | 300 | 3.29 | 5 x 5 |

CVB748-R5 | 48 oz. Crystal View Bowl | 6.78″ | 4.36″ | 15.35 | 300 | 3.49 | 5 x 4 |

CVB7LID-R5 | Lid For Crystal View Bowl | 6.78″ | 0.90″ | 9.14 | 300 | 2.62 | 5 x 6 |

Sushi Bases and Lids – Pagoda

Part Number | Description | L x W x H (in.) | Case Weight | Case Ct. | Cube | Ti x Hi |

|---|---|---|---|---|---|---|

R0267-P7509B | 9×5 Sushi Base – Pagoda | 7.36 x 5.20 x 0.90 | 17.67 | 720 | 1.24 | 5 x 15 |

R0267-P7515L | 9×5 Sushi Lid – Pagoda | 7.68 x 5.52 x 1.50 | 20.31 | 720 | 4.20 | 6 x 4 |

R0267-P9512B | 7×5 Sushi Base -Pagoda | 9.41 x 4.57 x 1.20 | 18.09 | 660 | 1.22 | 6 x 12 |

R0267-P9515L | 7×5 Sushi Lid – Pagoda | 9.73 x 4.89 x 1.50 | 23.96 | 660 | 4.30 | 6 x 4 |

Post-Consumer PET can be utilized for D&W Fine Pack’s entire line of PET products.

View examples below, check out our PET catalog, or Contact Us today!